Product categories

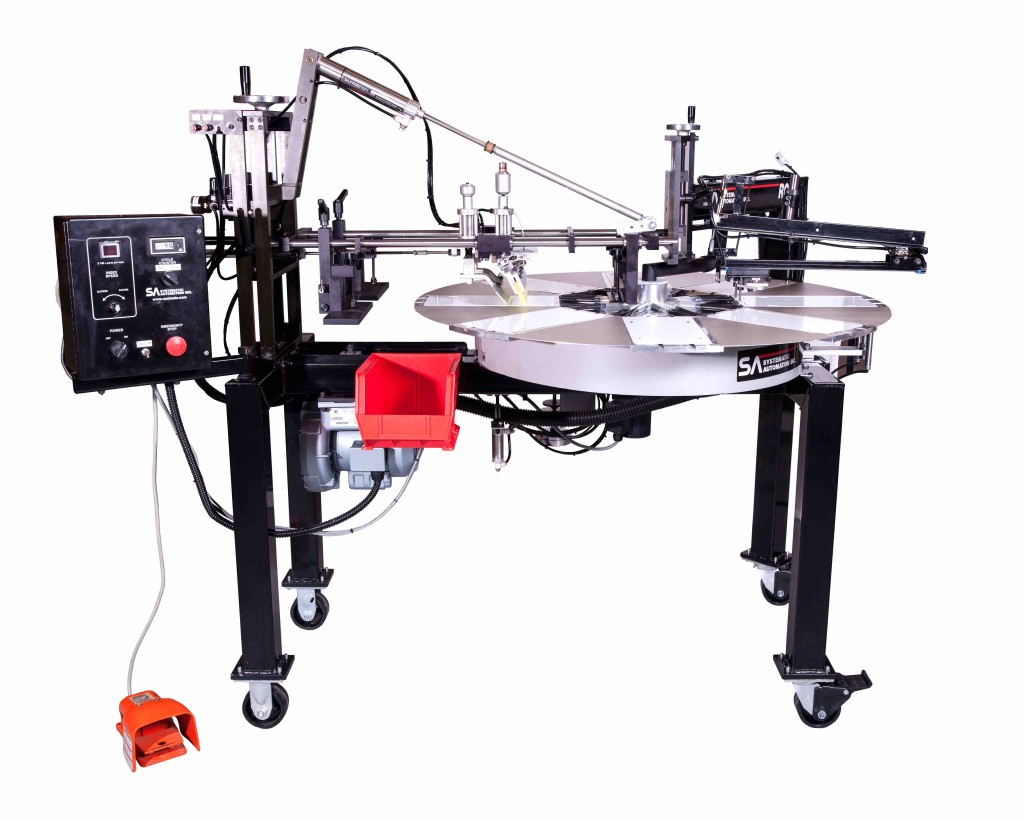

F1 Screen Printing Machine

- Designed for simplicity and precision screen printing.

- Approximately 3,600 prints per hour (depending on product).

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

- Capability to print flat & cylindrical products.

- Pneumatic system cannot overload, burn out, or become obsolete.

810 Screen Printing Machine

- User friendly control panel.

- Capability to print flat & cylindrical products.

- Approximately 3,600 prints per hour (depending on product).

- Top quality linear ball bearings rated at over 300 million cycles.

- Pneumatic systems cannot overload or burn out.

SST Screen Printing Machine

- Ideal for panels, windshields, sheet stock, plaques and more.

- Top quality linear ball bearings rated at over 300 million cycles.

- Extremely accurate sliding table position.

- Table servo drive coupling features overload/crash protection.

RC-1 Screen Printing Machine

- Ideal for license plates, 3D products, shoe insoles and more.

- Top quality linear ball bearings rated at over 300 million cycles.

- Approximately 3,600 prints per hour (depending on product).

- Machine can operate in single cycle or fully automatic mode.

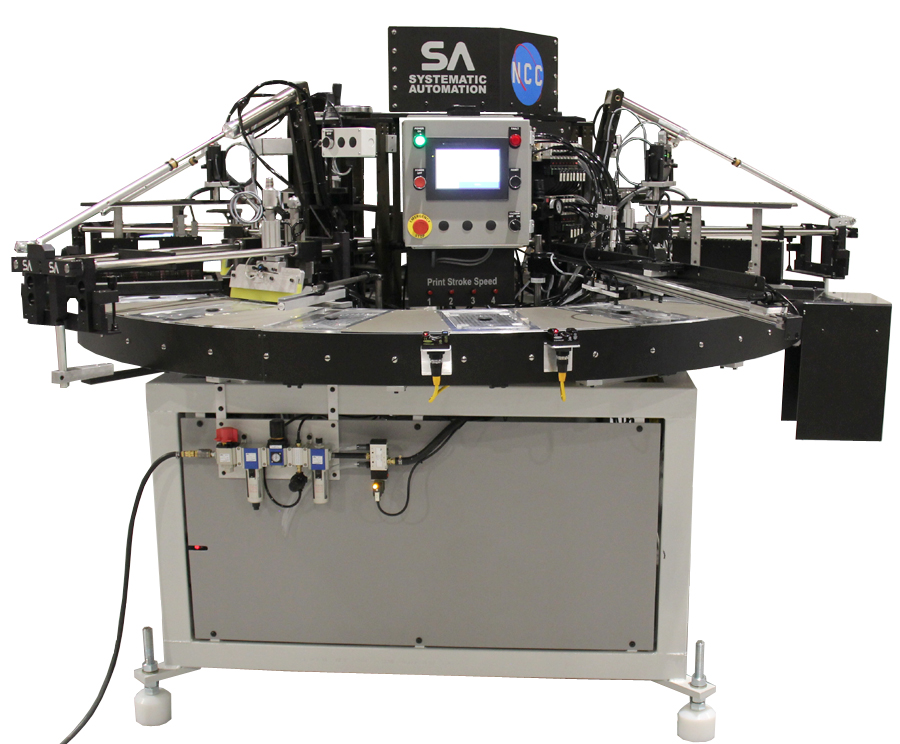

NCC Screen Printing Machine

- Highest quality servo motor drive and reducer are used.

- Approximately 3,600 prints per hour (depending on product).

- Modular design permits easy modification and integration.

- Electronic positioning of extreme accuracy +/-.001″(.025 mm) at all stations.

- Hollow Ring™ dial to servo drive coupling is overload crash protected.

HLT Screen Printing Machine | Flat & Cylindrical Products

- Ideal for rulers, plaques, panels, 3D products and more.

- Table features independently micro-adjustable X, Y and angular movements.

- 100% pneumatic operation that cannot overload or burnout.

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

SX Screen Printing Machine

- Ease of adaptation for loading and unloading systems.

- Approximately 3,600 prints per hour.

- Hardened track and roller bearings.

- Lubrication of critical friction parts.

- User friendly touch screen system.

Sliding Table Series Screen Printer | Flat Products

- Ideal for 3D products, plates, panels and more.

- Top quality linear ball bearings rated at over 300 million cycles.

- Pneumatic system cannot overload or burn out, or become obsolete.

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

CC-5000 Screen Printing Machine

- Ideal for cards, poker chips, tokens, nail files and more.

- Approximately 5,000 prints per hour.

- Top quality linear ball bearings rated at over 300 million cycles.

- Pneumatic system cannot overload, burn out or become obsolete.

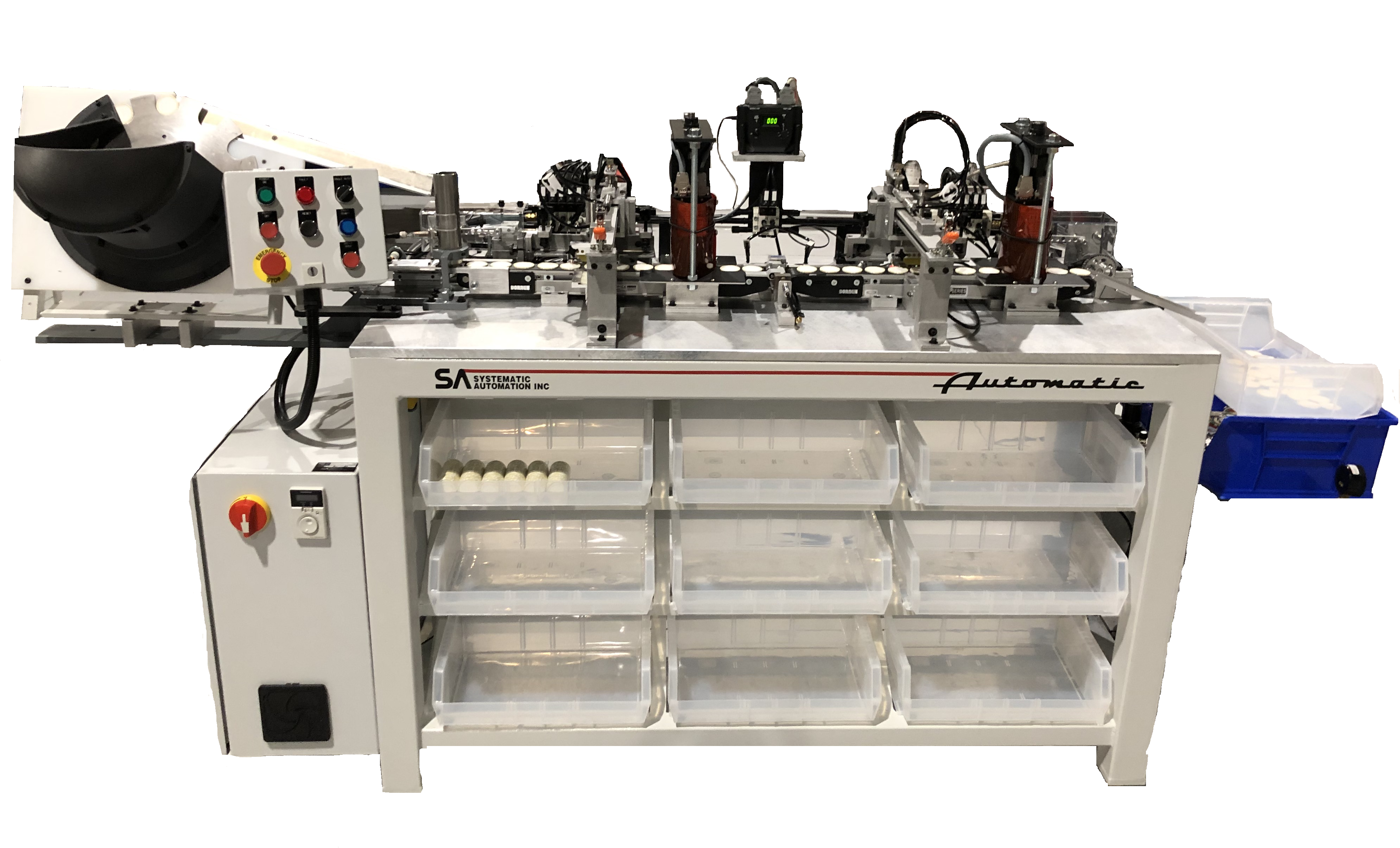

Microscope Slide Screen Printing Machine

- Approximately 3,600 prints per hour.

- Glass chipping is nearly 100% eliminated.

- Automatic loader including load magazines and pick & place.

- 2-axis automatic unload robot including unload slide gripper.

PRINT Belt Screen Printing Machine

- Revolutionary design – no tooling/fixtures required

- Modular design lets you print any flat product, regardless of size and shape

- Multicolor printing with conventional UV, LED and heat tunnel available

- Modular design allows for process integration such as automatic loading, unloading, pretreatment, vision and more.

Ultra LED UV Conveyor

- Custom conveyor/LED size to your specification.

- Programmable scale factor in different units.

- Best in class energy efficiency.

- Unique conveyor pulley design for perfect belt tracking.

Ultra Light UV Conveyor

-

- Tri-Power 200/300/400 watts per inch power supply.

- Lamp sizes up to 40″(1010mm). Conveyor belt width sizes up to 144″(1450mm).

- Cooling air is drawn through unit by a blower.

- LED integration available.

- Plate belting available for heavy products.

- Adjustable lamp/LED module distance.

- Programmable power supply with PLC.

Read More

MC-1 Screen Printing Machine | Flat Products

- Aluminum tooling plate base, ground flat within +/- .001” (0.025 mm).

- Universal screen frame holder.

- Screen frame holder can be separated for cleaning and reattached with no loss of registration.

- Spring loaded, screen up and down counter balance force adjustment.

Read More