UVSP | UV Curing Machine

- Ideal for glassware, bottles and more.

- Product is rotated parallel to the UV source focal point – 6″(154mm) & 12″(305mm).

- Exclusive revolving door design protects operators from escaping light.

- Universal vacuum product handling.

- Large systems available – up to 25″(635mm) lamp sizes.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for? Feel free to browse by screen printing application.

- Product Description

- Features

- Featured In

- Typical Applications

Product Description

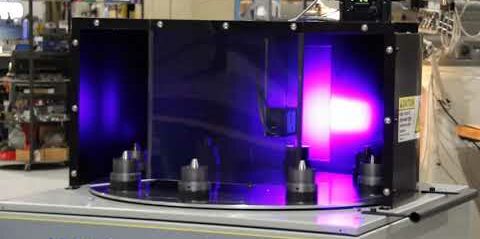

Focused Uniform UV Coverage For Your Cylindrical Products

The UVSP (U.S. Patent # 6,397,491 B1) UV Curing Machine for cylindrical products is designed for those who demand outstanding UV curing performance, energy efficiency and the highest return on investment. The UVSP has a true focused 360 degree cure, not uneven and marginal “spin on the fly” curing as found on conventional UV tunnel conveyor systems. And there is direct UV exposure that does not rely on mirrors for 360 degree coverage, which you will find with conventional UV tunnel systems. Mirrors degrade UV intensity by over 60 percent.The UVSP utilizes reflectors to reflect light from the ends of the irradiator back onto the work surface for maximum possible energy efficiency.The combination of the UVSP and the Ultra Light UV System offers value through technologically advanced designs that increase uptime and lower operating costs.

Features

- Entire print area is rotated through the UV focal point to maximize the effect of the UV light rays. Uniformity of cure is guaranteed.

- Universal vacuum plates securely hold most cylindrical products without the need for special holding nests. Dedicated tooling made for odd shaped products.

- Uses an all mechanical Geneva indexer with a brilliantly simple overload clutch. The Geneva indexer provides harmonic (smooth acceleration and deceleration) dial motion.

- The indexer is driven by a 110 volt variable speed AC Tech brushless motor. The motor is rated for continuous operation.

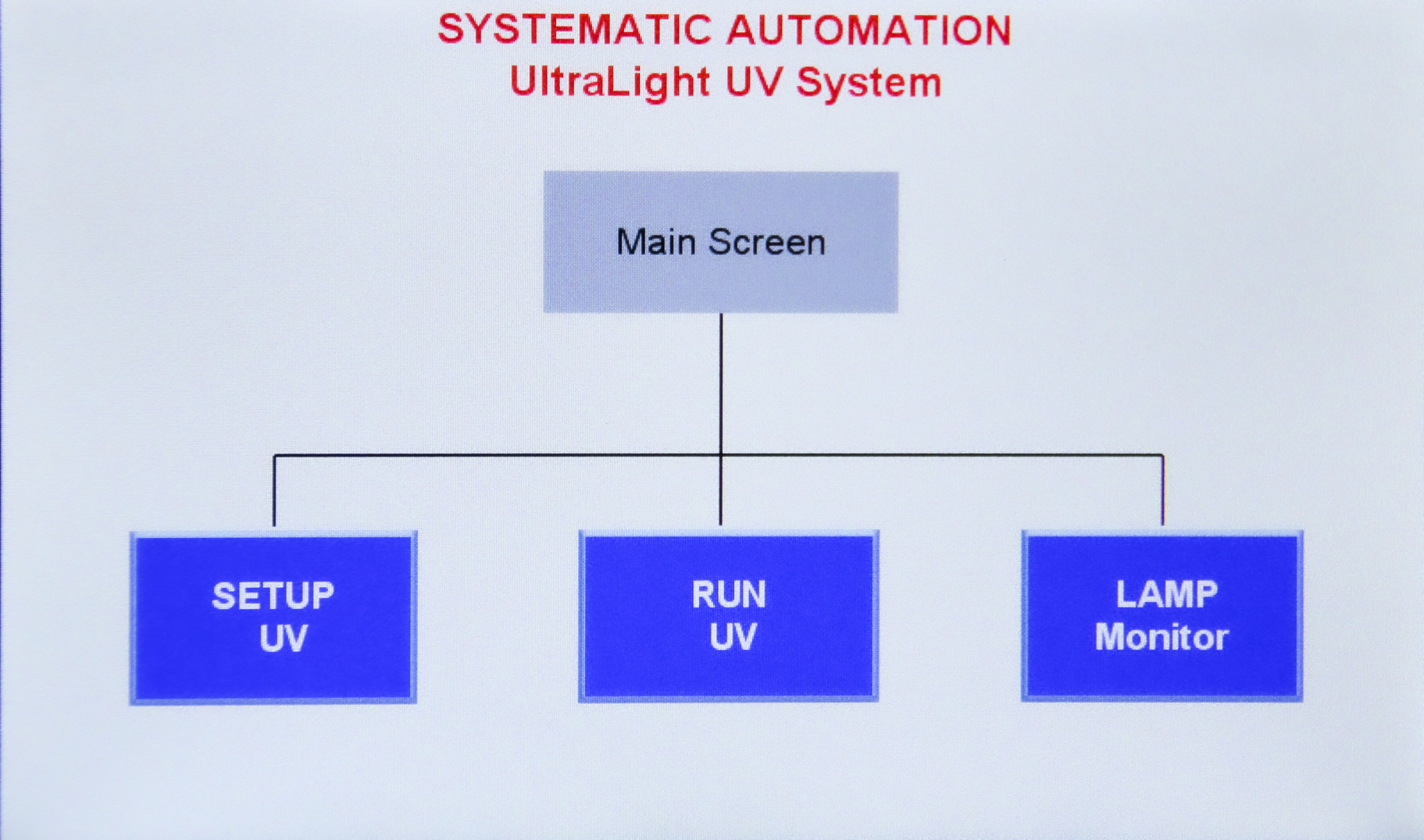

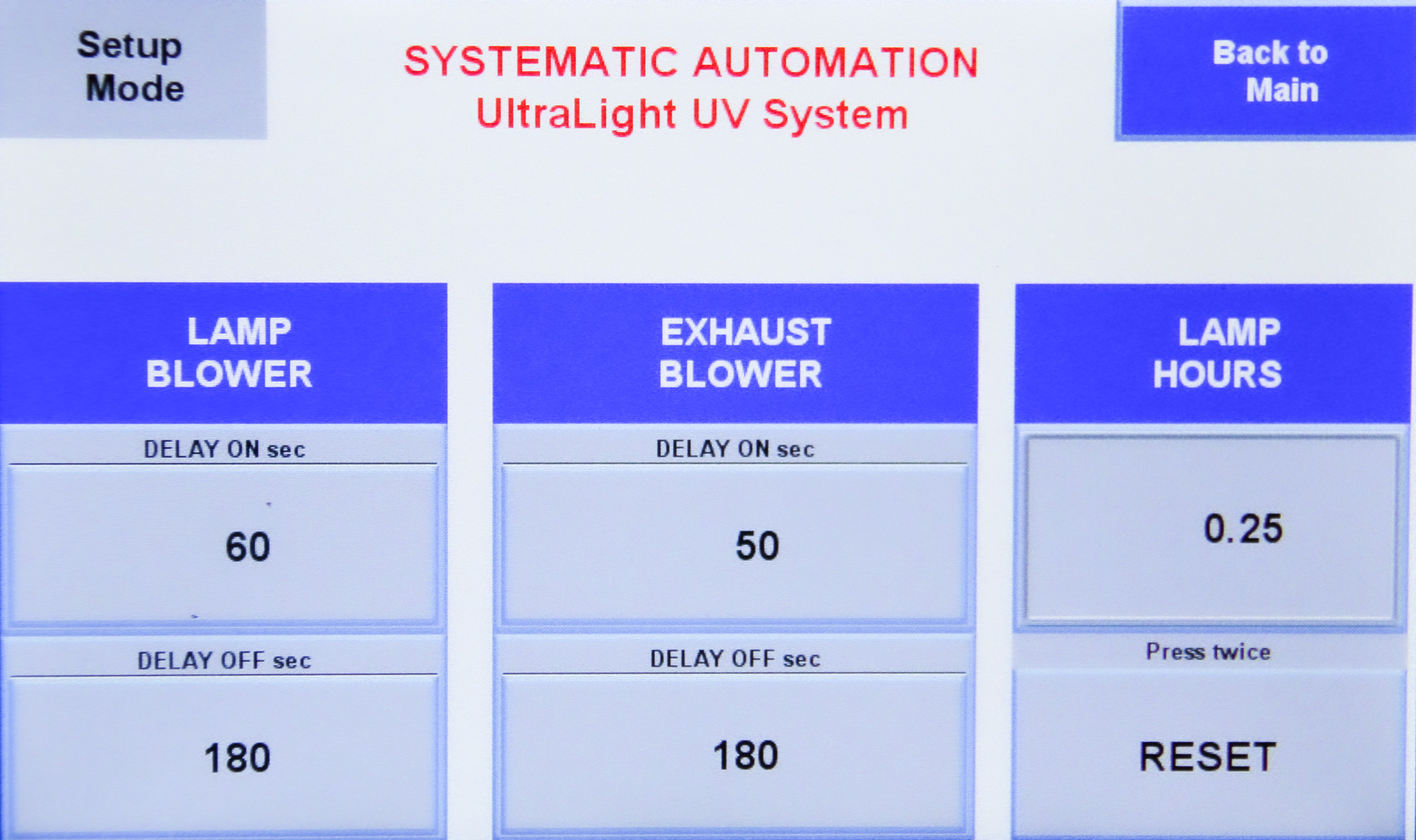

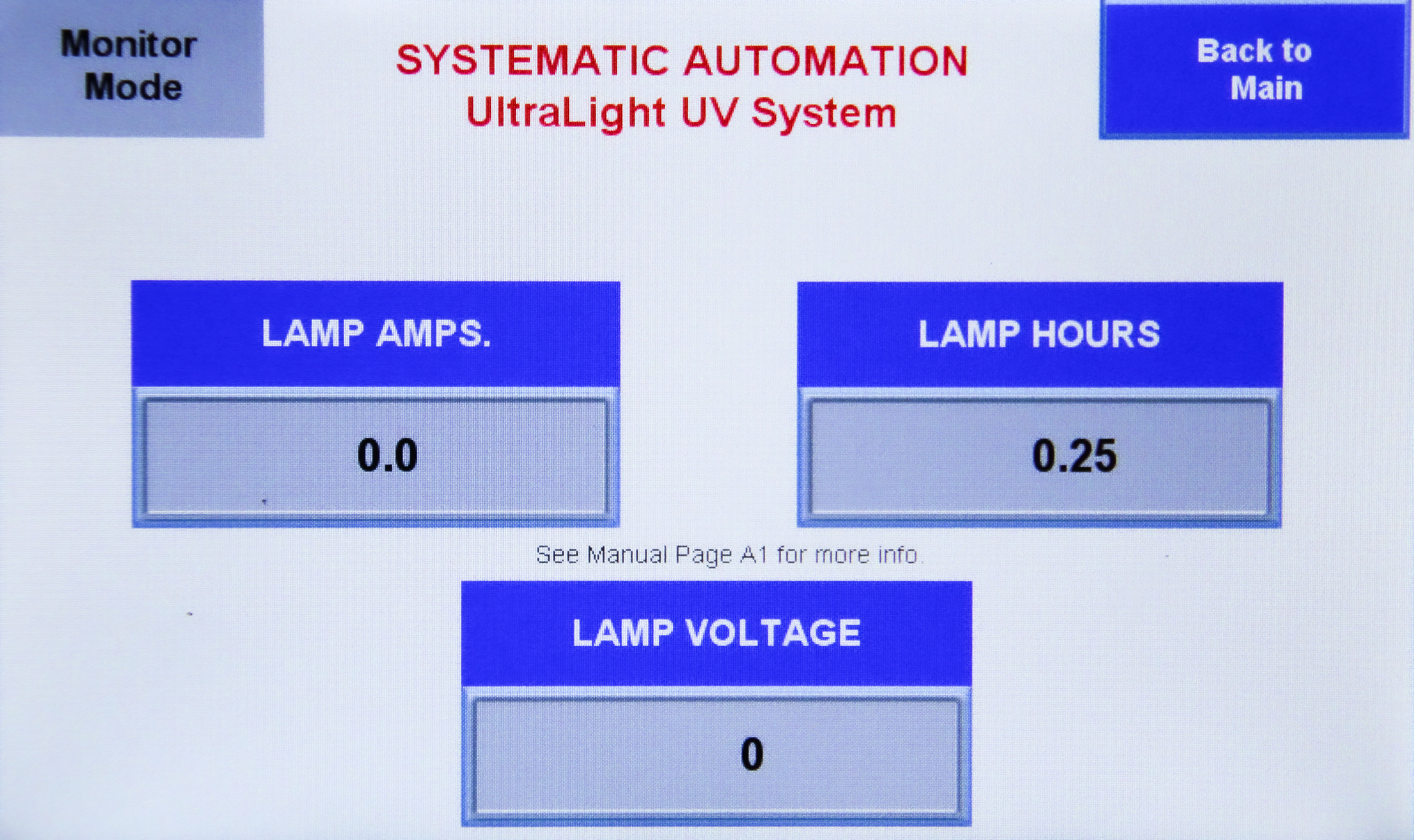

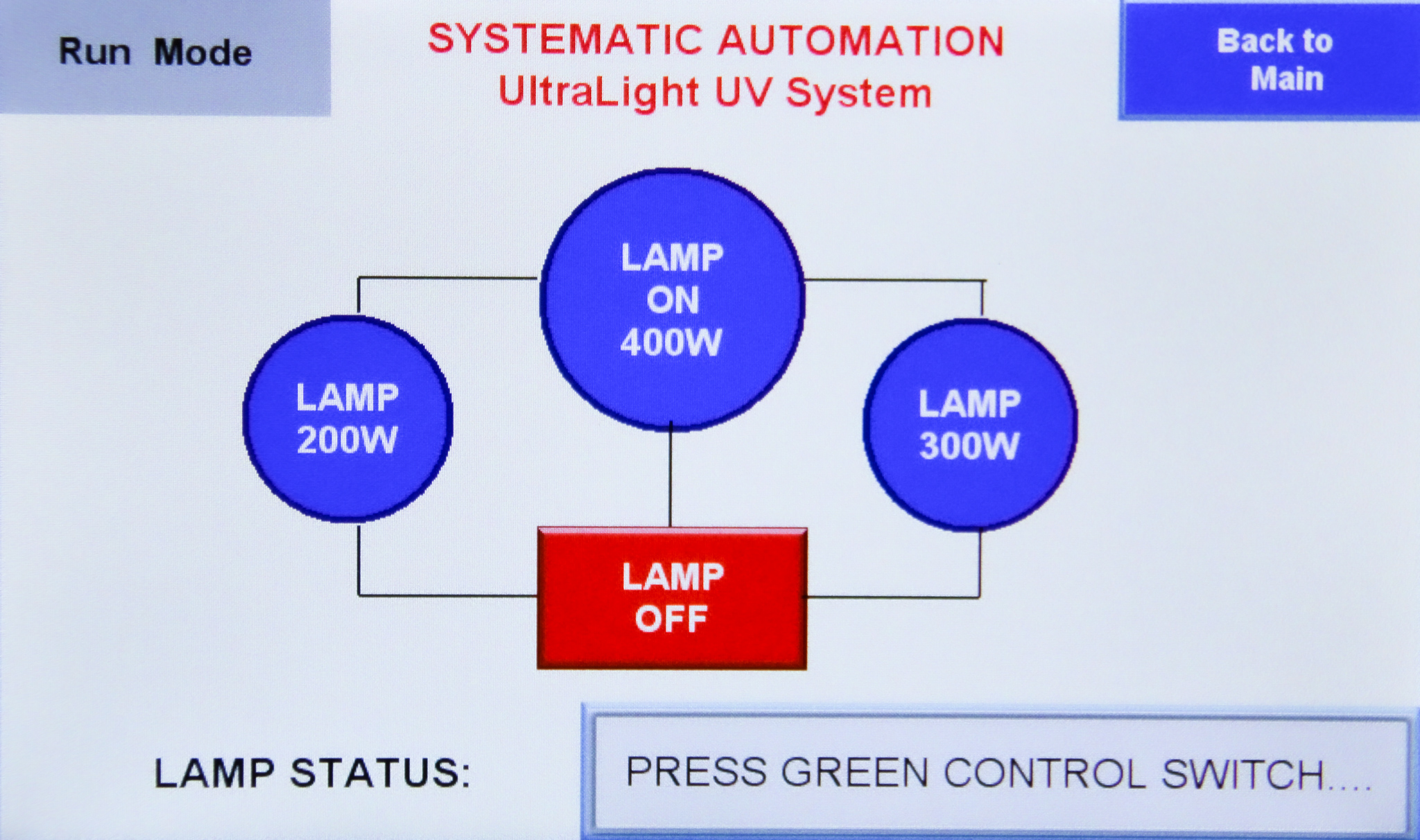

User Interface

Features

Engineering Features

- Part flexibility for cylindrical and irregular shaped items. Sizes from ball point pen barrels to gallon containers.

- Entire print area is rotated through the UV focal point to maximize the effect of the UV light rays. Uniformity of cure is guaranteed.

- Exclusive revolving door design protects operators from escaping light.

- Rotating through the UV focal point allows for the fastest cycling time while ensuring thorough, consistent curing.

- Once parts are loaded, no rollers, belts, or escapements adjust. Changeover from one part to the next can’t get any easier.

- Overload clutch.

- Machine control technique entirely eliminates the problem of electrical component obsolescence.

- Geneva indexer provides harmonic (smooth acceleration and deceleration) dial motion.

- Whether curing inks, coatings, or adhesives, the UVSP system allows adjustment of indexing and rotation speed as well as UV intensity.

- Compact design.

- Affordable price.

Standard Features

- Length 48″ (1219 mm).

- Width 36″ (914 mm).

- Height 60″ (1524 mm).

- Sizes: 6″ (152 mm) lamp, 12″ (304 mm) lamp, 18″ (457 mm) lamp and larger versions available built to your specifications.

- Maximum substrate height 15″ (381 mm).

- Maximum substrate diameter 14″ (356 mm).

- Variable speed AC motor control with digital readout.

- 400 watts per inch for 6″ (152 mm) lamps. Tri-power (200/300/400 watts per inch) available.

- Tri-power (200/300/400 watts per inch) standard for 12″ (304 mm) and longer lamps.

- Electrical requirement for 6″ (152 mm) system: 208-240 volts, 1 phase, 60 HZ.

- Electrical requirement for 12″ (304 mm) system: 208-480 volts, 1 phase, 60 HZ.

- Machine weight: 600 lbs. (272 Kg).

Featured In

Typical Applications

- Pint Glasses

- Plastic Bottles

- Growlers

- Shot Glasses

- Mugs

- Drinkware

- Glassware

- 3D Objects