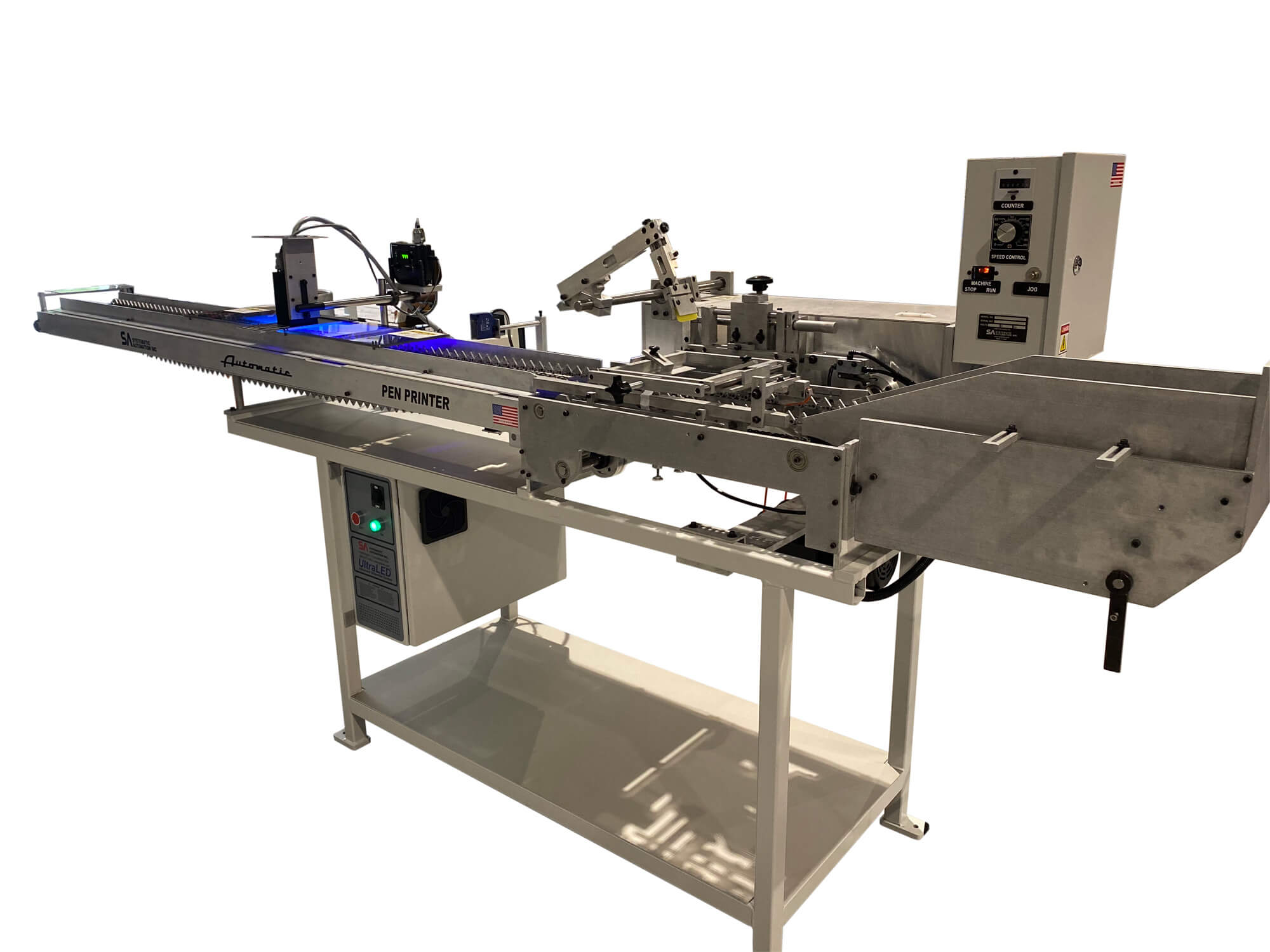

Screen Printing Machines

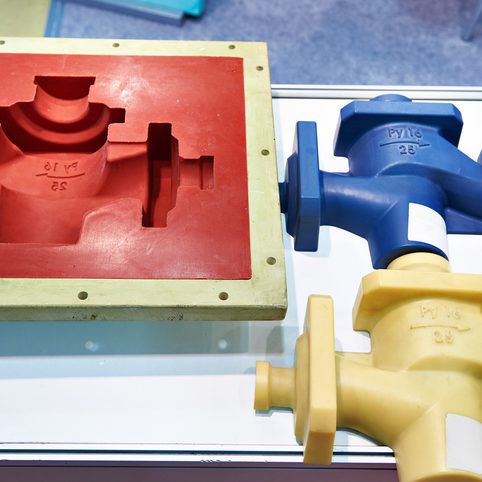

Automatic and Semi-Automatic Presses Designed For Your Business

Printing should be the most profitable part of your business. What you need is a total printing solution. Systematic Automation Inc. is the world’s foremost supplier of low cost, precision screen printing machines, with over 10,000 installations up and running in dozens of industries. No other vendor can offer as potent a combination of cutting-edge machinery. And no other vendor can bring it all together so seamlessly, giving your decorating team the tools and the know-how they need to get the work done. Now you can deliver your decorated products faster, better, and at a lower cost. If the business decisions are yours, the printing system should be ours.

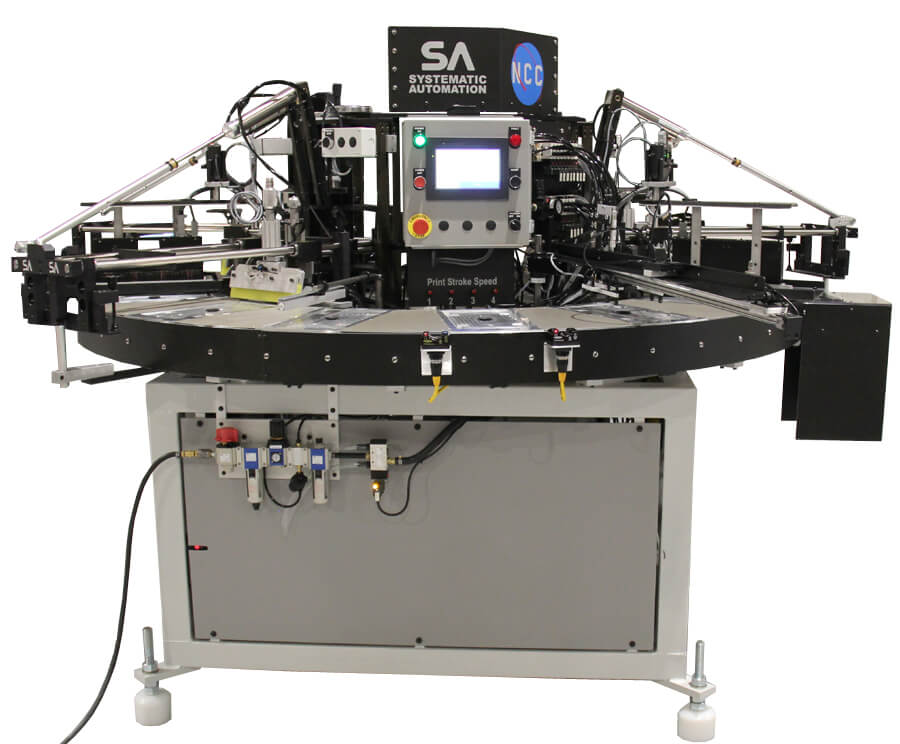

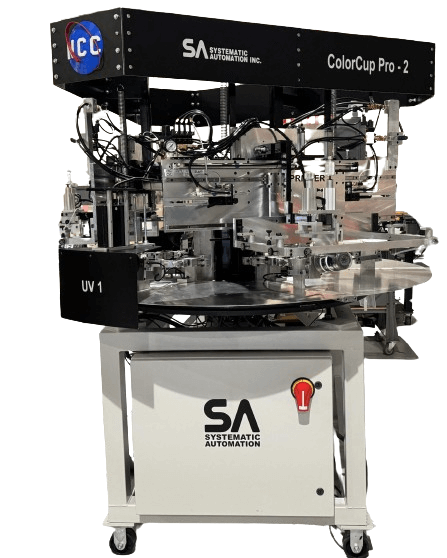

- Designed for simplicity and precision screen printing.

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

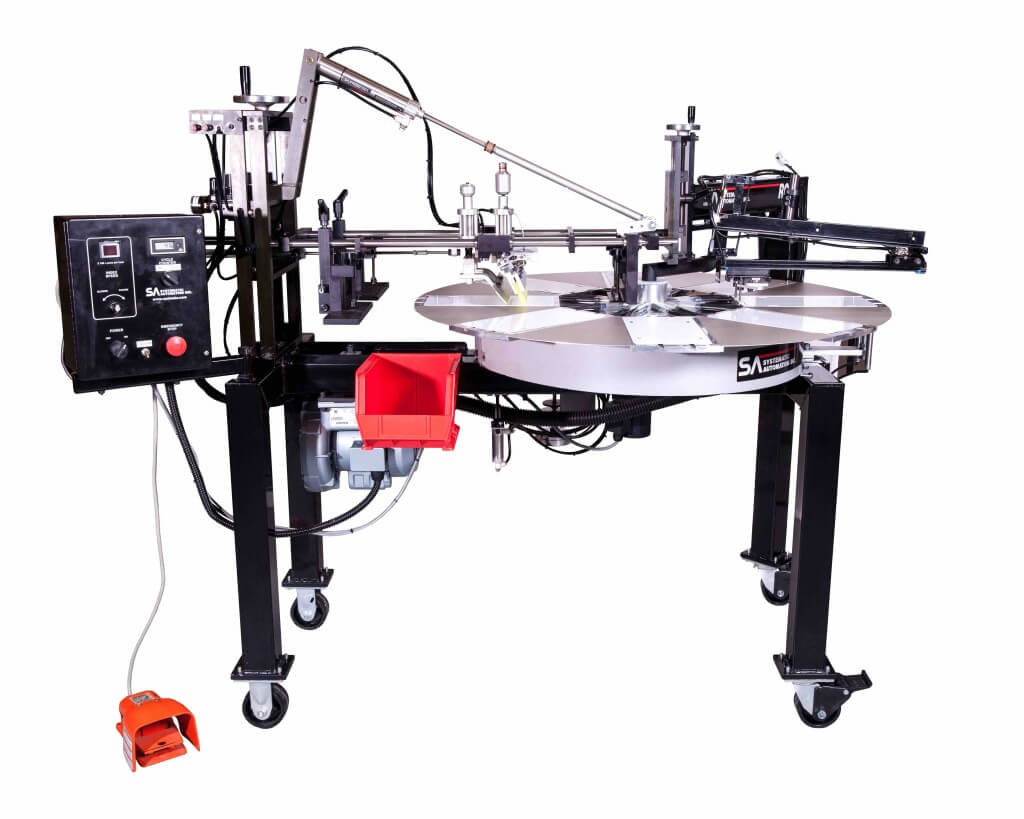

- Capability to print flat & cylindrical products.

- Pneumatic system cannot overload, burn out, or become obsolete.

- Ideal for cups, pint glasses, wine glasses, growlers and more.

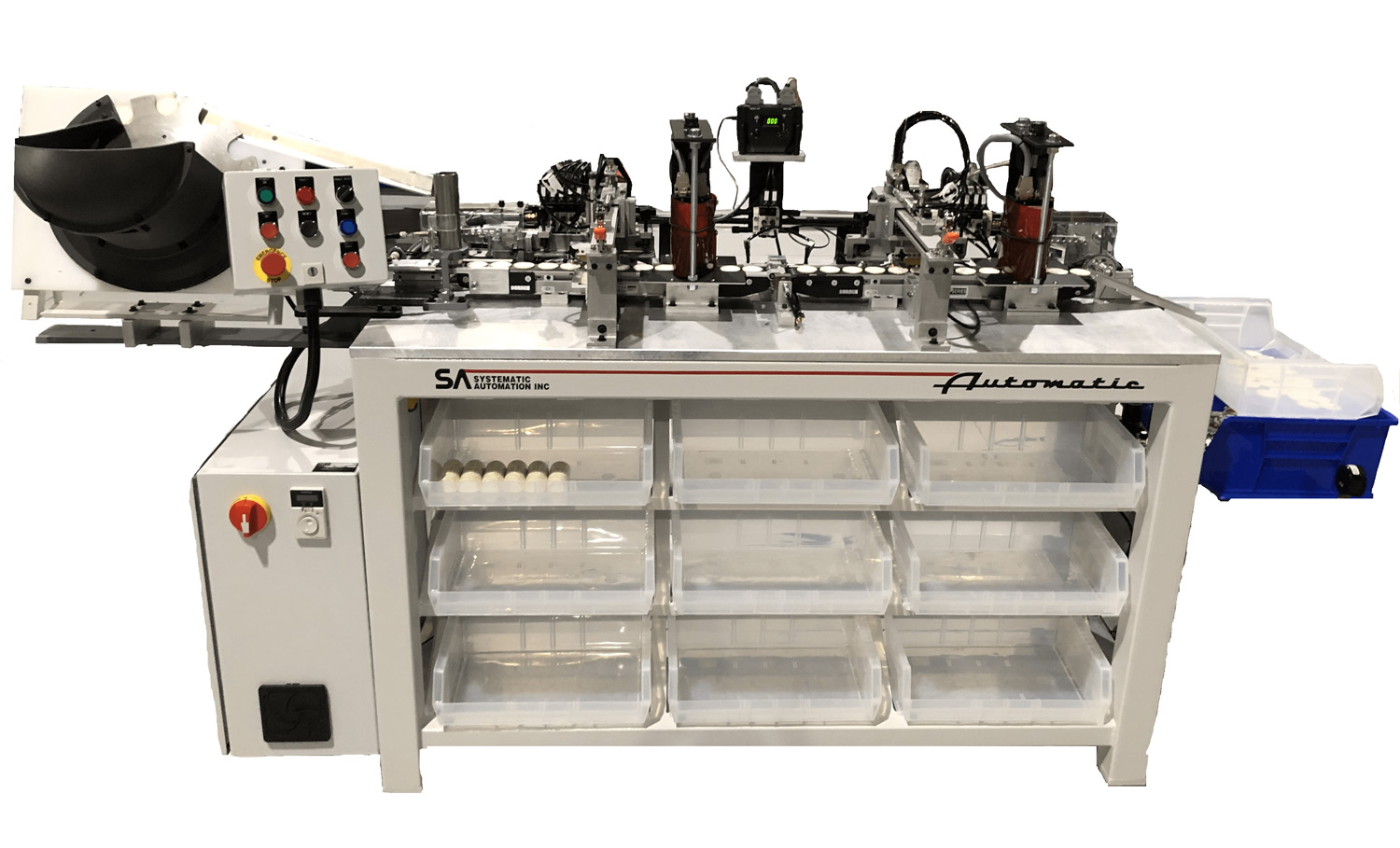

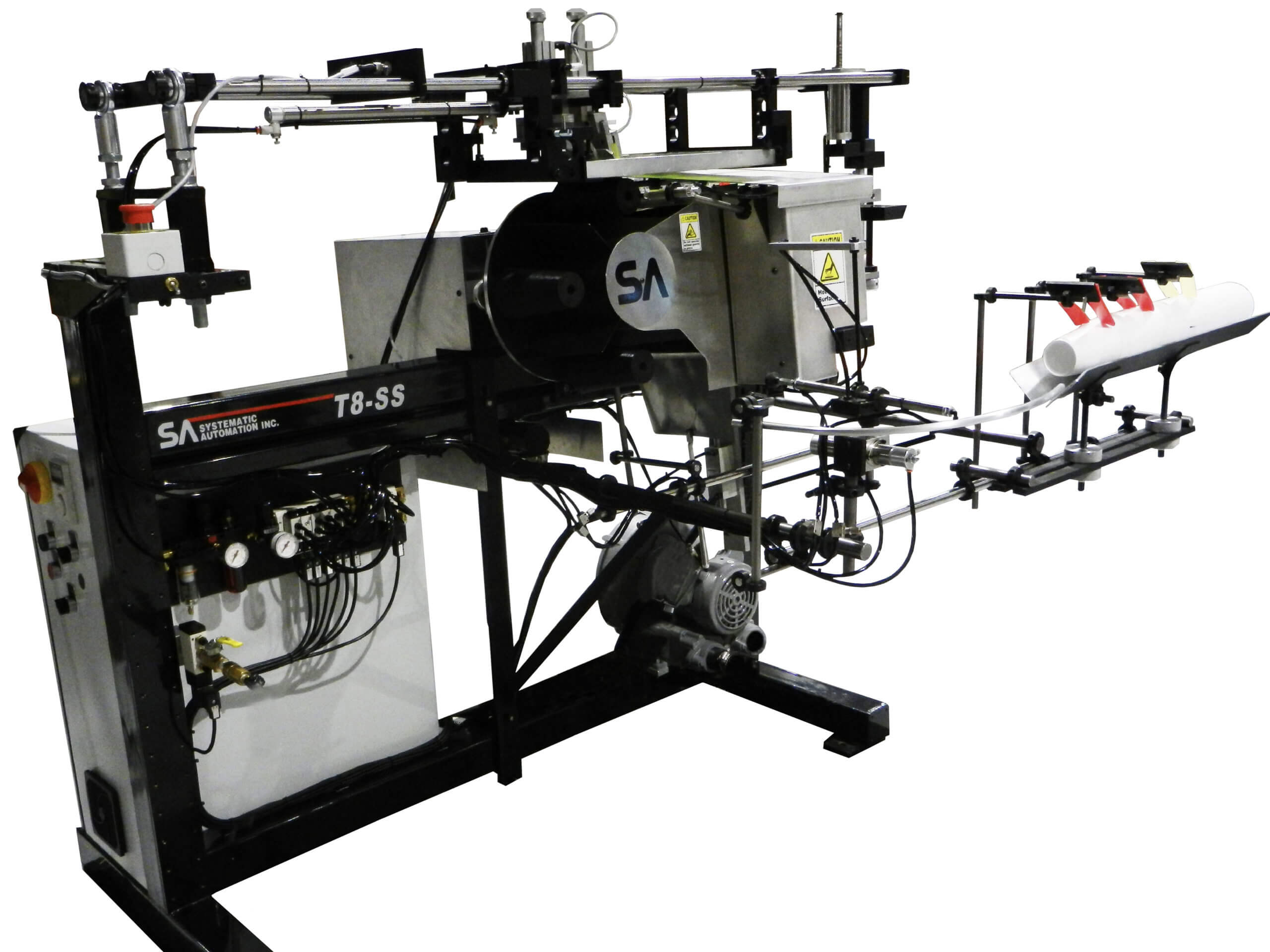

- Built for demanding production and designed for simplicity.

- Quick and easy product changeover in seconds.

- Approximate throughput of 3,600 parts per hour (depending on article).

Manufacturing Industry Solutions in the USA Since 1983

See our machines in action, printing on a variety of flat and cylindrical products!

Screen Printing Should be the Most Profitable Part of Your Business. What You Need is a Total Printing Solution.

Systematic Automation is the largest supplier globally of machines for imaging your products, with over 10,000 installations up and running in dozens of industries. We have developed several patented and proprietary products, continuing to deliver cost-effective and straightforward solutions for automating your flat and cylindrical screen printing production process in various applications, including electronic, promotional, automotive, aerospace, advertising, pharmaceutical, and more.

Our highly skilled staff and expert engineers give your team the tools and the know-how they need to deliver decorated products faster, better, and at a lower cost.

Revolutionary Screen Printing Machines

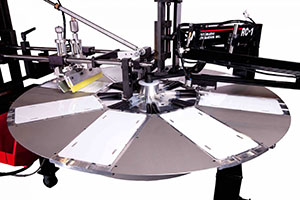

Systematic Automation, Inc.’s Model CC-5000 silk screen printing machine set the standard for automated screen printing with successful, efficient printing on various flat items, such as plastic cards, revolutionizing the screen printing industry. The CC-5000 comes with a design still utilized today after over 30 years of successful production, offering quick and simple changeovers and rapid and reliable performance at a low cost.

Since our inception over thirty years ago, we have designed, engineered, and manufactured over twenty various models of screen printing presses, providing versatility and efficiency in many industries around the globe. Our dedicated assembly areas with small machine assembly lines utilize the latest technology and components to provide you with top-of-the-line industry leading machines.

Diverse Screen Printing Industry Knowledge

Systematic Automation goes above and beyond standard suppliers. We also provide you with one full free day of training and offer continual phone support to ensure your printing project is successful. We can also customize auxiliary equipment such as conveyor belts for a more automated and cost-effective solution.

Questions? Call 860-677-6400, extension 112.

SOME OF OUR SATISFIED CUSTOMERS