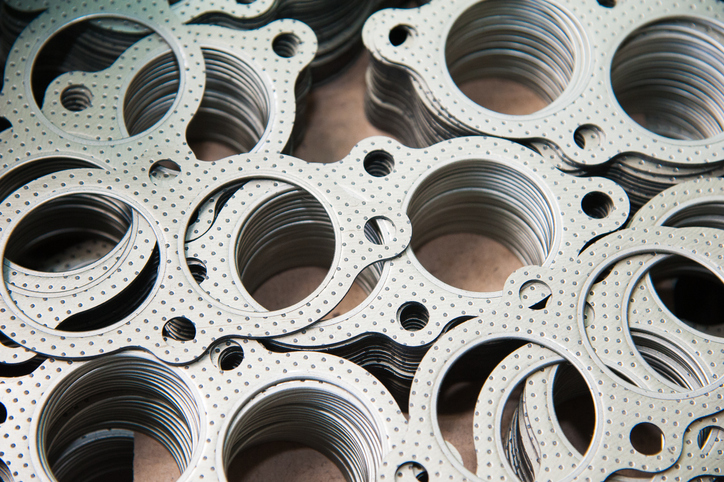

Screen Printing Machines for Gaskets

Our machines can handle all your automotive gasket needs. From punching to screen printing. Gaskets need to be precisely punched to ensure an accurate fit for your car or truck. Ensure you have the right machine for the job.

Our machines are perfect for branding your gaskets after the punch. We offer on/off magnetic tables to ensure accurate printing on your stainless steel gaskets. Our machines are customizable and have multiple attachments to help create a machine that works for your shop.

Why Systematic Automation for Your Gasket Printing?

Systematic Automation offers gasket screen printing machines for new printing businesses to established shops looking to upgrade their machines. We offer an array of custom screen-printing machines built right here in the U.S.A.

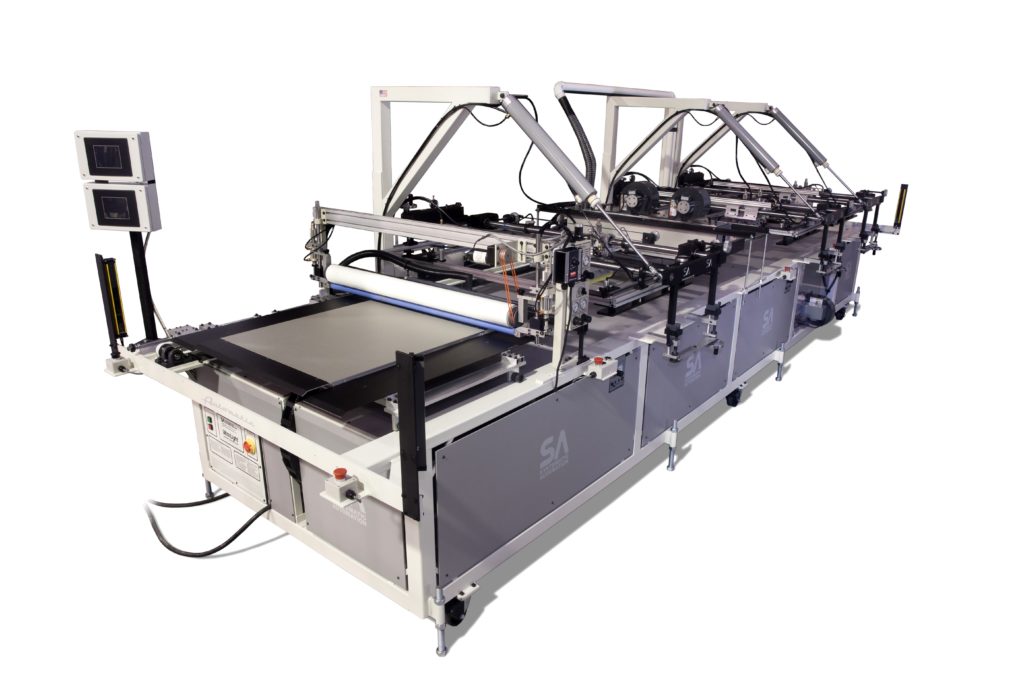

- The Model SST automatic screen printer offers the quality and versatility you need in your machine. The SST uses an on/off magnetic table and adjustable UV curing to give the best screen printing possible. The touch screen interface makes using the SST easy for all skill levels. The modular design of the SST allows you to incorporate other parts of your process on the machine such as punching systems that can punch holes on the template of your gaskets followed by printing and uv curing.

Printing your gaskets has never been simpler

- Ideal for panels, windshields, sheet stock, plaques, and more.

- Top-quality linear ball bearings rated at over 300 million cycles.

- Extremely accurate sliding table position.

- Table servo drive coupling features overload/crash protection.

Screen Printing Machines for Gaskets

-

SST Screen Printing Machine

SST Screen Printing Machine

Sliding Table Printers For Flat ProductsLearn More- Ideal for panels, windshields, sheet stock, plaques and more.

- Top quality linear ball bearings rated at over 300 million cycles.

- Extremely accurate sliding table position.

- Table servo drive coupling features overload/crash protection.

Make the Right Choice for Your Screen Printing Business

Systematic Automation is your choice for professional custom screen-printing machines made here in the U.S.A. We offer an array of custom screen-printing machine models to handle all your printing needs. We also offer UV curing machines, vacuum tables, and heat treatment machines to ensure your printing shop can fill every order. We have experienced technicians that offer support to help set up your machine and any technical questions you have once you start printing. Call or contact us today to speak with one of our expert technicians and choose the right machines for your business.

Some of our satisfied customers