SOME OF OUR SATISFIED CUSTOMERS

SYSTEMATIC AUTOMATION SCREEN PRINTING MACHINE MANUFACTURER

Systematic Automation has been making screen printing machines, UV curing machines, pretreatment systems, and vacuum tables for 40 years. SA has been engineering industry leading machines & providing proven solutions since 1983. Every SA product is built & designed in the USA.

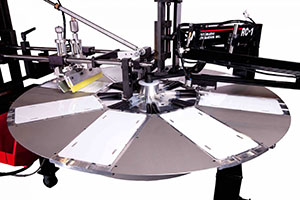

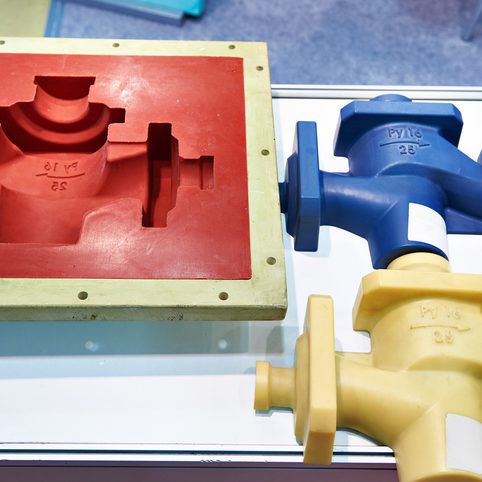

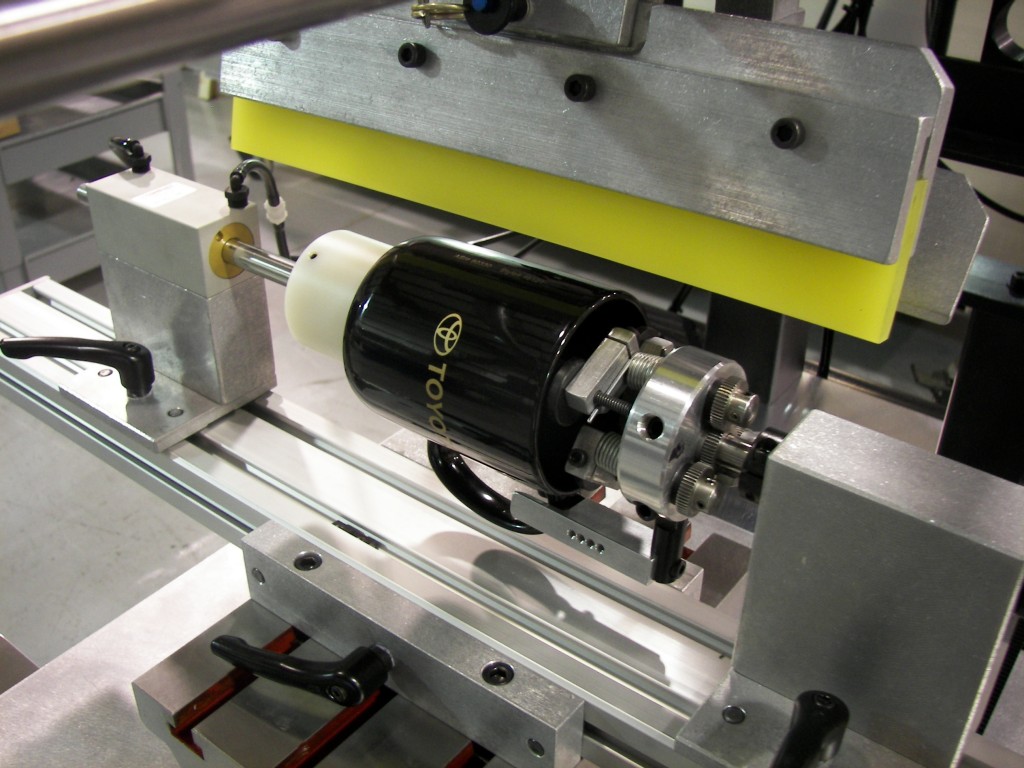

SCREEN PRINTING MACHINES

- Industry standard printing for your flat & cylindrical products.

- Manufactured for precision printing for single and multicolor designs.

- Modular machine options for your products and process.

- Machines are domestically supported in the USA.

Why screen print?

- Most affordable means of printing. Ideal for large product runs.

- Unparalled opaque and vibrant image quality.

- Achieve high-resolution prints with fine details and intricate designs.

- Used on a wide variety of surfaces, including textiles, paper, glass, metal, and plastic.

UV CURING SYSTEMS

- For UV curing your flat and cylindrical products.

- Instantly cure your inks for quick product throughput.

- Lamp sizes up to 40″(101cm). Conveyor belts up to 144″(365cm).

- Tri-Power System (200/300/400 WPI) with Adjustable Settings. LED integration optional.

BUILT FOR PERFORMANCE

At Systematic Automation, we strive to increase the productivity of our customers through world class screen printing machines, uv curing systems and vacuum tables.

World Class Screen Printing Machines

Systematic Automation screen printing machines can handle a nearly infinite variety of products. We manufacture machines that can print on cylindrical, flat, rigid and flexible products. Our machines are designed to lower your printing costs, and increase your productivity.

Exceptional Flame Treatment Machines

Systematic Automation is a leading manufacturer of flame treatment equipment such as our patent pending flame treatment design to provide 360 degree coverage of all types of cylindrical products.

UV Curing Systems for Inks, Coatings and Adhesives

For both conventional UV curing systems and LED curing, Systematic Automation has you covered. From equipment design to after sale servicing as well as parts, Systematic Automation prides itself in being a one stop shop for all your UV curing needs.

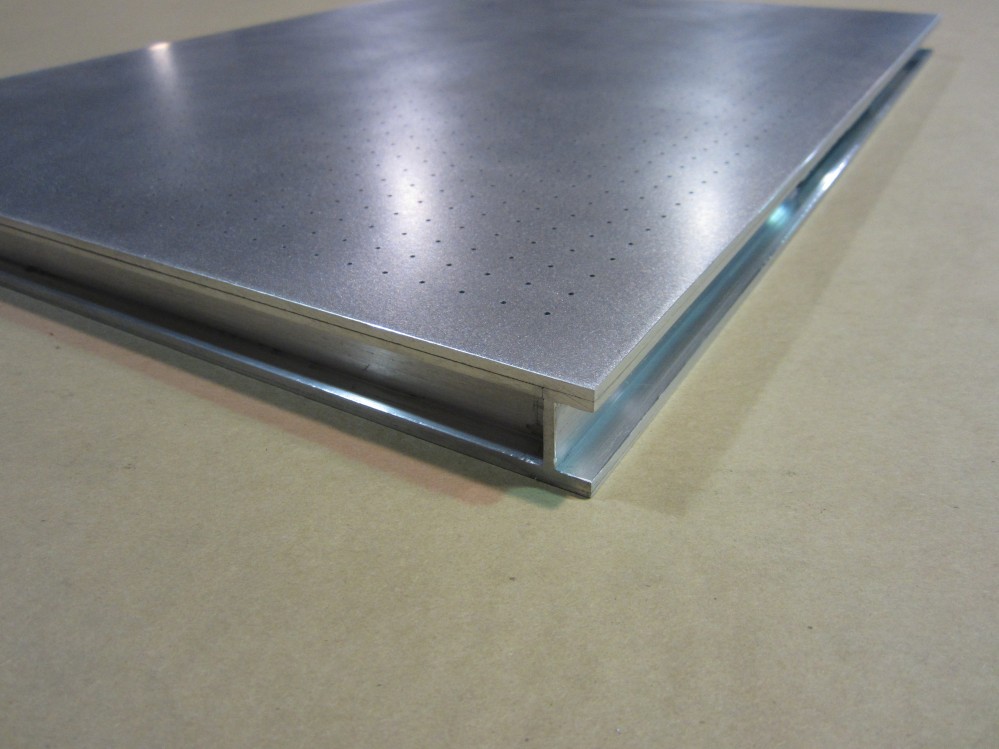

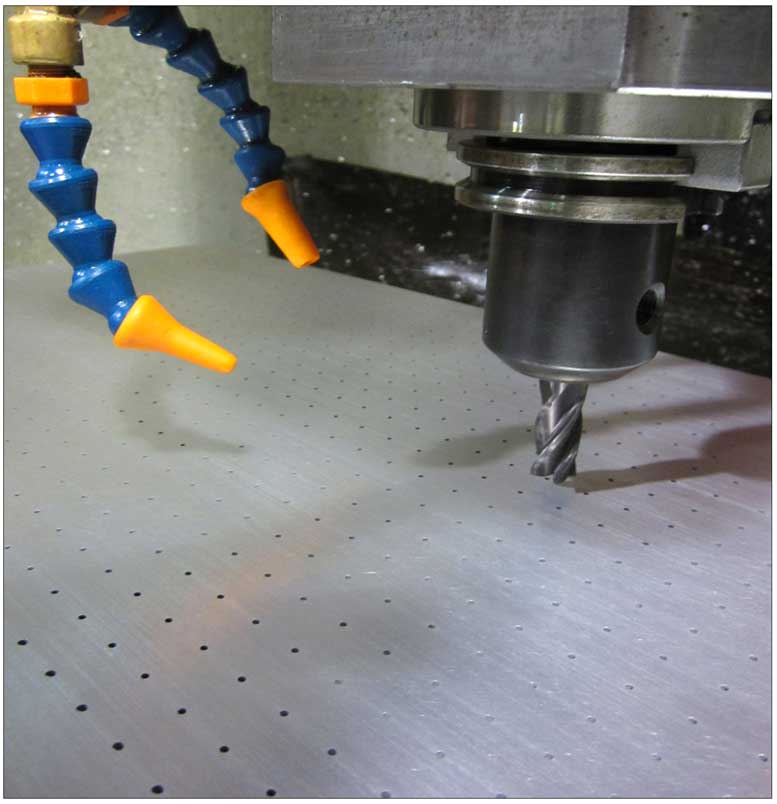

Custom Vacuum Tables

For over 30 years our vacuum tables have been designed and manufactured to the highest possible tolerances. Because we offer so many different options, we can customize vacuum tables for your specific vacuum application. We also have extensive experience in providing vacuum tables with CNC capabilities. Contact us today and let us create that vacuum table that is just right for you.

The Many Benefits of Automatic Mug Printing Machines

Computers have found their way into every aspect of this modern world including screen printing with automatic mug printing machine options. Screen printing machine manufacturers embrace computerized control with programmable logic controllers (PLCs), bringing digital technology to the screen printing industry. PLCs operate from microprocessors similar to those that power computers, replacing analog machine controls…

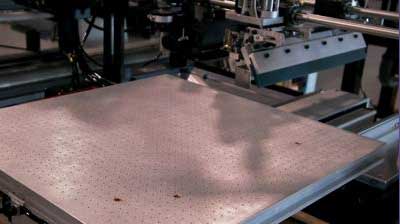

Read MoreScreen Printing Vacuum Table Equals Winning Combination

Combining screen printing with vacuum table systems provides many benefits which greatly improve product quality and process efficiency. Screen printing machines which utilize vacuum systems realize greater product quality as substrates do not move during the printing processes for precision printing. This is true of many different products such as printing on small parts for…

Read MoreVacuum Clamping Tables Designed to Your Application

Vacuum clamping tables are the preferred hold down method in many commercial and industrial processes. Vacuum tables offer many advantages over other hold down methods such as jigs, screws and adhesives. Utilizing controllable vacuum force to keep substrates securely in place during precision processes such as cutting or grinding provides quick changeovers, consistent flatness and…

Read MoreWhy a CNC Vacuum Bed is the Best Hold Down Method

When choosing the best hold down method for your CNC application, it is important to evaluate the benefits of using a CNC vacuum bed. Vacuum systems provide hold down force during many processes, keeping various substrates and materials firmly in place during applications such as cutting and grinding. Critical applications which utilize computer numerically controlled…

Read More