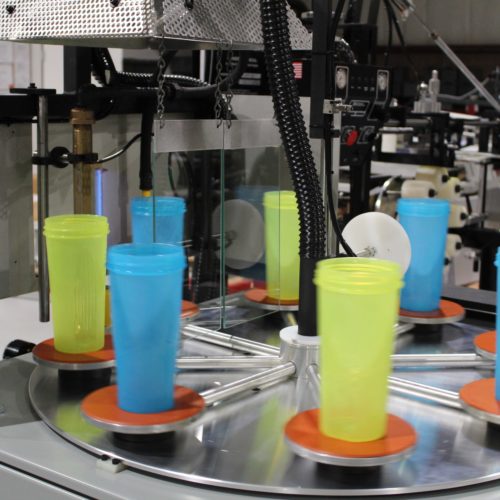

flame treating plastic

Benefits of Flame Treatment for Plastic Surface Treatment

When looking for the best method for plastic surface treatment, be sure to know the benefits of flame treatment systems. The nonporous surface of most plastic products makes bonding with outer coatings such as varnishes, laminates or screen printing impossible without pre-treating the plastic surface. Quality designed flame treatment systems provide surface treatment solutions with…

Read More